Case Study: Creating Value with ESG Solutions for Frac Sand: Sil Industrial Minerals, Catapult Solutions and Crew Energy Inc. Collaborate to Meet ESG Commitments

Background:

Crew Energy Inc. (“Crew”) is always looking for ways to reduce their environmental impact, improve safety performance, and increase the efficiency of their BC Montney operations. They have previously implemented water transfer through existing pipelines to frac sites, as well as using natural gas in drilling and frac operations which not only reduces cost, but further minimizes greenhouse gas emissions. To continue on the path of improvement, the opportunity to utilize locally sourced frac sand came with not only a cost reduction, but an important environmental benefit: lower GHG emissions.

This opportunity would require keen focus on cost competiveness, logistics, and of course, collaboration with the right “partners”.

Crew appreciated the enormity of their mission. If they could accomplish this, they would now have taken another significant CLIMATE ACTION step forward.

The Collaboration:

- Sil Industrial Minerals (“Sil”)

- Canada’s leading frac sand producer with corresponding transportation and distribution assets across AB, BC and SK

- Production and logistics capacity to exceed even the most intense daily pad records of 6000 MT/day

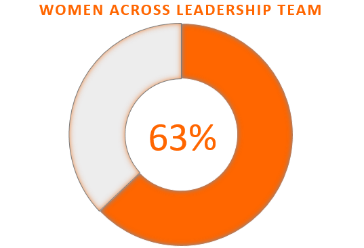

- Female leadership and ownership

- Proud Canadian job creators for over 50 years

- Catapult™ Solutions Ltd. (“Catapult”)

- Industry leading last mile frac sand wellsite storage system

- A Clean Tech Solution invented and manufactured right here in Canada

- Proudly deployed across North America to export Canada’s Clean Tech Solutions

- Female Canadian inventor, founder and ownership

Sil Industrial Minerals and Catapult™’s ESG performance

Catapult™ last mile frac sand wellsite storage system

The Project:

- West Septimus field in Northeast B.C.

- Montney formation

- 4 Well Pad

- 20,000 Tonnes Pumped over 14 Days

The Plan:

Sil Industrial Minerals provided Crew with a full bundled service for their complete proppant (“frac sand”) requirements, including a fully operated Catapult™ Solutions on-site proppant management system:

- The proppant was supplied by Sil Industrial Minerals. The majority was hauled directly from Sil’s Bruderheim plant, but Sil utilized its Montney transload as required, without additional cost, in order to optimize its transport fleet efficiency to manage fluctuations in daily wellsite consumption

- The proppant logistics were coordinated between Sil’s on-site personnel and its logistics experts

- Catapult™ Solutions supplied its on-site proppant management system and specialized personnel to manage the systems and offload transport units. Catapult’s system included its proprietary Prop-Up™ dual conveying unit and Propensity™ storage bins, which discharge on demand into the service company’s blender

Now, what story would be worth reading without some drama?

As Sil initiated supply to the wellsite, the industry was suddenly subjected to a rail strike. Crew wondered how this might impact them, as other energy producers and service companies scrambled to secure all available local frac sand supply and every possible transport unit. The industry did not find themselves without access to the local frac sand, but they were suddenly faced with NPT on most wellsites while they waited to find trucks to haul the frac sand.

Despite the legitimate concern, Sil Industrial Minerals has its own transport fleet. So, the project continued without interruption, without additional costs, and without NPT costs that would have accompanied the interruption.

The Commitments |

The Results |

|---|---|

| 1. GHG Reduction for Drilling & Completions |

|

| 2. Deliver Leading Safety Results |

|

| 3. Reducing Environmental Footprint & Ground Disturbance |

|

| 4. Expanding its Work with Women in Energy |

|

| 5. Support Local Businesses & Economy |

|

| 6. Reduce Completions Costs |

|

| 7. Achieve Superior Well Performance |

|

Greenhouse gas reduction on the Project within the Montney formation as a result of delivering frac sand from Sil Industrial Minerals’ mine versus imported frac sand.

Watch the video to learn more.

ESG Solutions Which Deliver Value and Frac Efficiency to WCSB Wellsites:

In today’s economic climate, Canadian exploration and production companies must focus on creating cost efficiencies in their completion programs. And yet there is growing commitments to improve ESG performance.

Fortunately, not all sizeable ESG solutions come at a price. Sil and Catapult have worked to deliver a combination of essential cost savings, together with innovation which drives critical ESG outcomes for the WCSB:

- WCSB is trending to high-intensity fracs over short periods of time. This requires a focus on efficient and predictable frac sand supply. Sil has the capacity and logistics capabilities to be a key partner for even the largest daily demands of these “Fracs of the Future”.

- Sil offers strong ESG performance throughout its mining, processing and reclamation operations

- Combining Sil and Catapult creates an opportunity for significant environment and safety advantages by capitalizing on substantially shorter transportation distances than when using imported frac sand:

- BC Montney: 55% reduction in GHG emissions

- AB Montney: 58% reduction in GHG emissions

- Duvernay: 73% reduction in GHG emissions

By choosing Sil and Catapult for their frac sand and last mile requirements, exploration and production companies can leverage this ESG performance as a source of competitive advantage.